Ultra light

Carbon fiber is 5 times lighter than steel and nearly 2 times lighter than aluminum for the same volume.

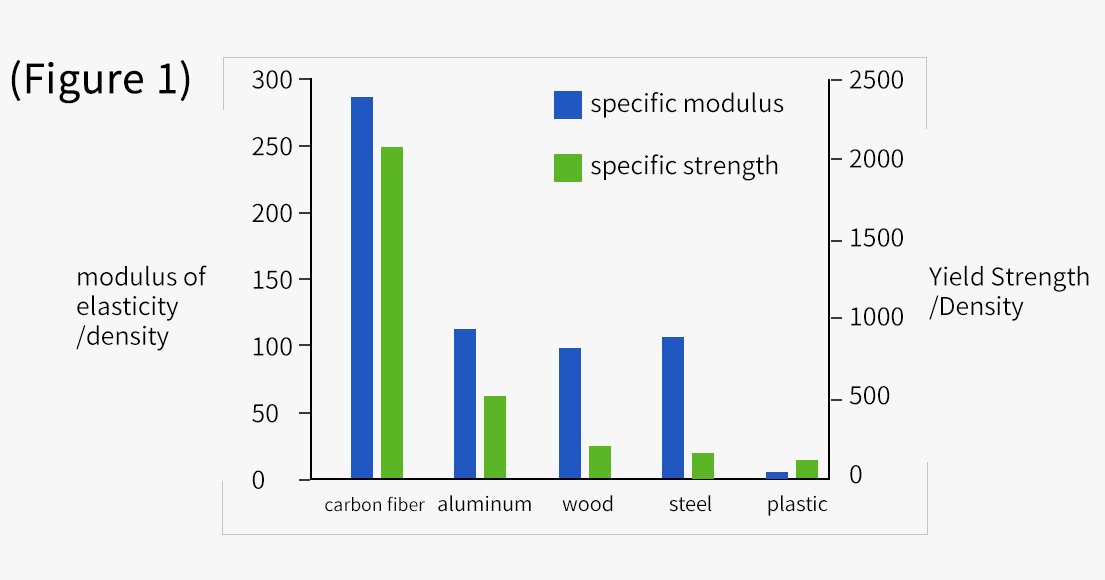

High strength

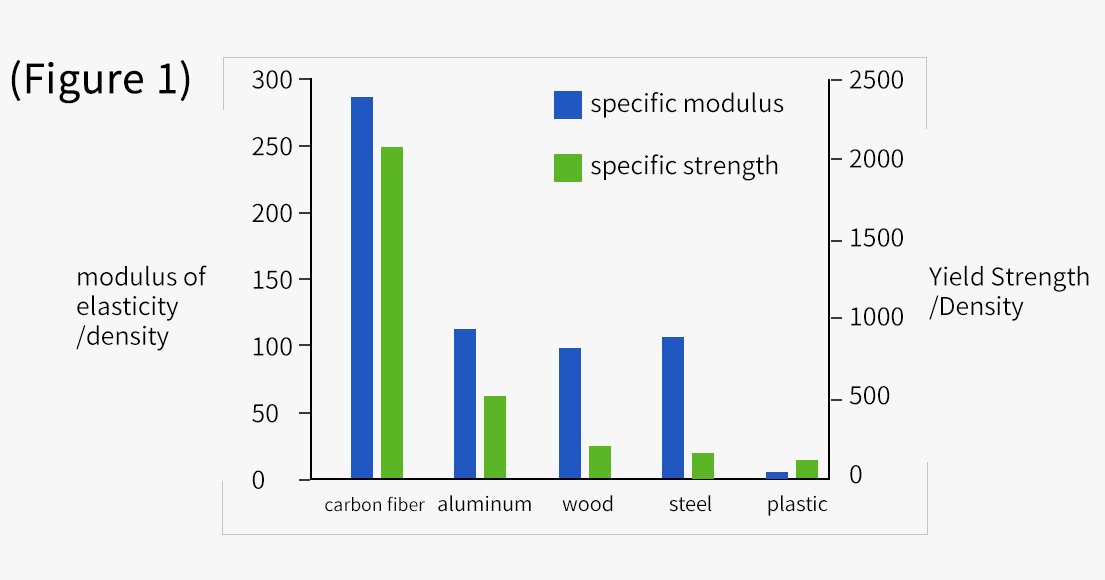

Compared to metal, plastic and wood, carbon fiber is dense and stiff.(Figure 1)

Corrosion resistance

Epoxy resins are inert, do not easily corrode or rust, and the carbon bonds in the fibers are extremely strong and resistant to oxidation.

Low thermal expansion

Metal expands when heated, causing problems and possible failure of parts. Carbon fiber has virtually no thermal expansion.

Musical instrument

Due to its high strength, light weight and low damping, carbon fiber has become ideal for musical instrument construction material, capable of making instruments comparable to the most expensive wooden models.

Sports equipment

The increased strength-to-weight ratio of the carbon fiber material not only makes the racket lighter, but it also allows for better control over the manufacturing process and racket quality for improved comfort, control and power swing in use.

Rockets and spacecraft are subjected to extreme loads when they are launched into space. In order to survive,They must be constructed of strong and durable materials. Another important factor in a rocket launch isweight, which is why carbon fiber is the material of choice for the aerospace industry.

Drone

Carbon fiber materials are ideal for fuselage components and rotor arms for recreational or industrial drones.

Water sports

Carbon fiber can be used in a wide range of applications from diving fins to kayak accessories and boat construction and decoration.

Transportation

Whether you're looking to save weight, or you're looking to save money for your RV, car, truck, ATV,To add some style to a motorcycle or scooter, carbon fiber can be used for many different purposes.

SAVA bike

Carbon fiber has the best parameters for weight, stiffness, durability and ease of use in bicycle manufacturing. Therefore, it can withstand high impacts, allowing athletes to reach the finish line faster.

Low thermal conductivity

Metals act as conductors and can transfer or radiate heat to the surroundings and cause heat soaking. In comparison, the thermal conductivity of carbon fiber is very low.

Radiolucent

Carbon fiber is transparent to radiation and invisible in X-rays.

Advantages of carbon fiber frames

While ensuring light weight, rigidity, and shock absorption, the carbon fiber itself has both soft and machinable properties. Through aerodynamic performance testing and research and development, the geometric angle and airflow path of the frame are optimized to improve the wind breaking performance of the frame. Riders can handle headwinds or crosswinds with ease and maximize their riding speed. This kind of performance can best reflect its advantages when climbing, it is smooth and refreshing, not like an aluminum alloy frame, there is a kind of backward pulling force.

Advantages of carbon fiber forks

The molding method of carbon fiber is to lay fiber sheets on the mold and then flow into the resin for sintering, which can be made into frames of various shapes. This urban-type characteristic determines the formation of the newly designed lightweight super streamlined carbon fiber front fork. After a series of tricks and improvements, the front The weight of the fork reduces the resistance and improves its lateral rigidity, so that it has a unique wind-breaking structure, realizes the precise handling of the bicycle, and becomes the best guiding travel helper for the rider.

Advantages of carbon fiber wheels

It is very important for a rider to have a pair of solid and reliable wheels. The new carbon fiber rim design allows the bicycle to widen the width of the inner and outer rims, while also meeting the requirements of light weight and rigidity of the rim, which well realizes the aerodynamic effect, making the flow through the wheel set table.

The airflow on the surface is more stable and stable, making it possible to start lightly and accelerate quickly.